Mk4 Frame & Chassis

The Mk4 Frame & Chassis

We use an authentic 4” round tube design, and feel strongly that a quality replica should have a period correct, 4” round tube frame, just like the original legend. The tubular ladder-style frames used in the original 1960s AC cars are more than beautiful, they are representative of a period of automotive design that is legendary. We chose to use this style of frame despite the manufacturing difficulty and cost, since a huge part of a quality replica is its faithfulness to the spirit of the original cars.

While originality is very important, if the frame doesn’t perform, what good is it? We kept the design style, but used CAD technology, better materials, and more consistent manufacturing methods to make it more than twice as strong.

Since 1995, the Factory Five Roadster frame has become known for its strength and ability to protect its occupants. With over 800 welds and hundreds of individual pieces of steel, the Mk4 frame is both engineering excellence and functional automotive art. The frame is a completely welded assembly and requires no welding or cutting.

When you see Factory Five cars winning national races or lifting the tires clear off the ground, check out the “straight-as-an-arrow” frame quietly doing its job. There is no finer replica frame. Period.

A Great Car Starts with a Great Chassis. A chassis is the foundation of the house. Today’s fourth-generation Mk4 Roadster frame has benefited from years of refinement and development. It is both lightweight (376 lbs.) and strong.

We use high-quality, precision-cut plate steel with 1010 and 1020 DOM tubing. The Mk4 frame stands head and shoulders above the original 1965 legend thanks to better tools, better materials, and modern technology. Our welded parts are made in the USA with American labor.

Our welded parts are made in the USA with American labor.

Our welded parts are made in the USA with American labor.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

Mk4 Aluminum Panels

Underneath our hand-laid fiberglass composite body are almost 40 individual aluminum panels attached to the Factory Five Mk4 spaceframe.

Mk4 Aluminum Panels

Even vintage 1960s cars like the original ACs, Ferraris and GT-40s used proven racecar construction methods of tubular frames and riveted/bonded aluminum panels.

The aluminum chassis panels found in our Mk4 combines this traditional quality with the latest CAD/CAM technologies and superior construction methods. The entire cockpit, trunk and engine bay of the Factory Five Mk4 is precision laser-cut 6061-T6 aluminum, without any fiberglass structural items. Underneath these aluminum panels, a matrix of steel tubing provides support surfaces for a close, tight-fitting installation.

Why 6061-T6 aluminum? Conventional 4000-series aluminum is easier to bend and form, but not as strong in tension. We invested in learning how to correctly form the 6061-T6 to get the benefit of increased strength for the same weight.

The strong foundation of our world-class frame combined with our aluminum chassis panels bonded and riveted to it represents just one of the major design and functional differences between the Mk4 and almost every other replica sold today.

Mk4 Composite Body

The Mk4 Composite Body

The composite body is a one-piece, hand-laid vinylester part that is engineered to complement the strong steel and aluminum chassis, which provides structural support. The hood, doors and trunk have molded liners and come complete with hinges and pre-drilled mounting holes. The body shell is laminated to a thickness of 3/16” all around, with a .015” red gel coat outer finish.

The composite body is shipped pre-assembled to the frame. The parts are unfinished (requiring bodywork). Panels are CNC router trimmed.

We know molding. Since 1995, we’ve built and shipped more than 11,000 body shells and over 40,000 body panels, and built more than 100 complex molds and tools.

![]() “Station to station at Factory Five, it is clear that quality principles are in full force.”

“Station to station at Factory Five, it is clear that quality principles are in full force.”

Craig Fitzgerald | Editor, Hemmings Muscle Machines

Mk4 Suspension & Brakes

Front Suspension Base Kit

- Fully independent front suspension with unequal length upper and lower A-arms

- High-end KONI mono-tube adjustable coil-over rod-end shocks

- Uses donor Mustang front lower arms, spindles, and brakes

Front Suspension Complete Kit

- The Factory Five Racing Mk4 complete kit includes the entire front suspension assembly and Ford brakes

- Includes Ford GT brakes with 11” rotors, twin piston calipers, and stainless steel brake lines, fittings, and fasteners

- Includes brand-new spindles and tubular control arms

The Mk4 Roadster Kit is delivered ready to accept bolt-on rear suspension components in one of three rear suspension configurations:

- Four-Link Rear Suspension

Our standard 4-link is a great performance street car suspension. It comes with custom anti-squat geometry and is ready to accept Ford Mustang 8.8” solid axle donor rear suspension parts. - Three-Link Rear Suspension

The upgraded 3-link rear suspension is standard in Mk4 complete kits and all FFR Challenge Series cars. It includes the frame brackets, panhard bar, control arms, KONI mono-tube rod end coil-over shocks (matched to the fronts) and springs. Recognized as a proven and worthy upgrade to the standard Mustang 4-link, this suspension eliminates any bind and provides an amazingly predictable ride at the track or on the street. - Independent Rear Suspension

Our Independent Rear Suspension (IRS) option is designed for those looking for the most comfort, authenticity, and performance. The IRS can be added to either the base or the complete kit. It includes a welded-in cage, upper and lower tubular control arms, high-end KONI mono-tube rod-end coil-over shocks (matched to the fronts), and custom assembled axles and CV joints. The IRS option for the Mk4 kit requires the 8.8” center section, rear spindles, and brakes from a 2015 or later Ford Mustang.

Brakes/Wheels

The base Mk4 Roadster kit uses the rear-end and brakes from a 1987-2004 Mustang donor car. The Mk4 Roadster complete kit comes with brand-new front brakes including spindles and Ford Mustang GT 11” front rotors with twin piston PBR aluminum calipers. We offer a range of optional Halibrand replica wheels that are affordably priced and in the correct sizes/backspaces to work with our cars.

Mk4 Running Gear & Specifications

Mk4 Running Gear & Specifications

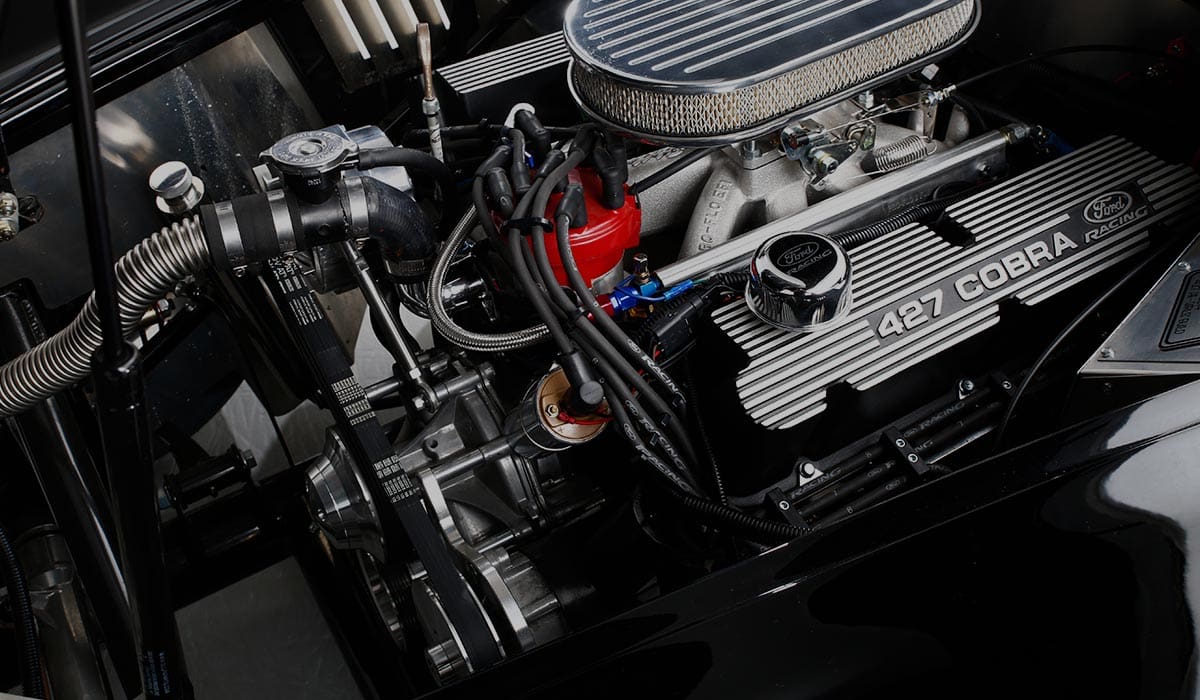

The Mk4 base kit is configured to use the entire engine/transmission/rear-end out of a 1987-2004 Mustang donor car (5.0 or 4.6 liter V-8, T-5, T-45, TKO, T-56, or 3650 transmission, and Ford 8.8” rear end). The kit is designed so that these parts literally bolt right in. You can use almost any Ford engine in the Factory Five Mk4. Select from:

- 289/302

- 351W and derivatives

- 390/427 FE

- 4.6L SOHC & DOHC Modular V8

- 5.0L Coyote Modular V8

- LS series

Suspension

- Front Suspension type: Independent double arm

- Rear Suspension type: Solid rear axle 4-link, 3-link with panhard bar, or IRS

- Shock-Springs: KONI coil-over with ride height adjustability

- Steering: Manual or power assisted rack and pinion

- Brakes: Vented 11/11.65 disc f/r

- Wheels: Vintage or modern 15”, 17”, or 18” diameter

- Tires: Common sizes are 245 series front/315 series rear

Vehicle

- Weight: 2,250 lbs.

- Weight Distribution F/R: 46.9/53.1 (percent)

- Wheelbase: 90 inches

- Overall Length: 158 inches

- Front Track: 58.5 inches

- Rear Track: 58.5 inches

- Overall Height: 48.0 inches

- Overall Width: 70.5 inches

- Ground Clearance: 4.5 inches

- Fuel Capacity: 15 gallons

Construction

- Layout: Front/mid engine RWD Roadster

- Frame: Twin tube space frame with integral backbone

- Roll Cage: 3-point, structurally mounted 1.5” DOM Tubing

- Sub-Structure: Aluminum paneling riveted and bonded to frame

- Restraint System: 5-point Simpson Harness

"...We like the Factory Five not only for the level of enjoyment a person can have with it strapped to his backside, but for the great engineering and business feat it is…"

Mk4 Interior

Mk4 Interior

Inside you’ll find the largest cockpit possible for the car’s authentic exterior dimensions. The Mk4 has good legroom and excellent front/rear visibility.

Mk4 kits include a complete interior:

- Original British style bucket seats in black with tubular steel

frames (not inexpensive fiberglass buckets); optional leather

seats are also available in black - Padded dash cover, aluminum dash, toggles and indicator

lights - Complete carpet set

- Emergency brake handle boot, shifter handle boot/ring, shifter and shifter knob

- Authentic door latches, door hinges and leather check straps

- All trim and gauges (or gauge conversion kit)

- 5-point Simpson racing H-harnesses for both driver and passenger

- Authentic wood/aluminum steering wheel with aluminum boss and center section

- Rolled edge along the entire cockpit

- We offer either modern or vintage-style electronic gauges, both made to match well with Ford electronics.

"...When it comes to bang-for-the-buck, Factory Five Racing's Mk4 is the Molotov cocktail of Replicas..."

Steve Temple, Editor Car Builder Magazine

Former Director of Marketing, Shelby American

Mk4 Exterior

Mk4 Exterior

Mk4 kits include complete exterior and trim:

- Authentic chrome-on-brass windscreen

- Vintage-style headlight assembly with DOT-compliant lighting

- Authentic style winged amber turn signals with improved DOT-compliant specifications

- Authentic style red dual tail/brake-lights, with DOT-compliant specs

- Original style polished stainless license plate light with DOT-compliant specifications

- Original chrome “bullet style” racing mirror and classic pedestal mount rear view mirror

- Authentic three-lock set (identically keyed) with L-shaped handles for hood and a T-shaped handle for the trunk

- Dual aluminum side louvers

- Beautifully crafted steel side pipes with integral mufflers (polished stainless steel is an available option)

- Original front and rear quick-jack bumpers with fasteners standard

- Authentic Aston LeMans flip-type gas cap with integral pressure cap and flared neck for fuel line hose

- High-quality trunk, door and hood hinges (hood hinge standard on the complete kit; available as an option on the base kit)

- Three-point, 0.120” wall DOM steel competition roll bar, powdercoated black; mounts directly to the frame with included stainless steel fasteners

Leader of the Pack!

The Factory Five Mk4 Roadster accurately maintains the essence of the original car, but uses modern technology, parts, and materials to improve performance and comfort. The Factory Five Mk4, with the 427 body style, is the best engineered, best performing, and best selling replica in the world.

Mk4 Safety

Mk4 Safety

In the world of hot rods, customs, and kits, we stand miles above the crowd. As the only replica company that has a dedicated racing series, we speak from a unique perspective.

We have a company that is single-minded in our passion for racing and performance, so safety is our daily religion. You can trust our products because the chassis that you build as a hot rod project is the same one that our team trusts with their lives on the track. Safety is a combination of good engineering, correct materials, and careful construction.

- Low vehicle center of gravity and balanced 47-53%

weight distribution - Energy absorbing tubular steel frame and aluminum chassis panels (not fiberglass)

- Front and rear energy-absorbing crumple zones

- SCCA-derived footbox steel tubing protection and cockpit steel surround structure

- Side impact bars and beefy plate steel door hinges

- Frame mounted doors

- Externally mounted and shielded fuel tank with fuel pump impact shut-off switch (from the Mustang donor)

- Collapsible steering column

- Driveshaft safety bars

- 3-point, 1.5” OD, .120” wall, mandrel bent, frame-mounted driver’s roll bar (optional passenger roll bar available)

- 5-point Simpson brand, racing H-harness for both driver and passenger

- Vintage components that are individually FMVSS compliant (i.e. lighting, carpets, seating material, safety glass, etc.)

- Manufacturing controls that maintain high degree of consistency in welding and fabrication

- Acceleration, turning and stopping abilities above almost any current production vehicle