Challenge Car Frame & Chassis

The Challenge Car Frame & Chassis

Challenge cars have left the pits and headed for the starting grid literally thousands of times since 1999. No other replica can even come close to the racing hours and track wins of the FFR Challenge car design. The Challenge car is not just completely dominant, it’s truly the only real race car in the entire replica business.

FFR Chief engineer Jim Schenck has been the steward of this car from it’s inception. Jim is an accomplished pro roadracer in his own right, and has earned countless race wins in almost 15 years of competitive driving.

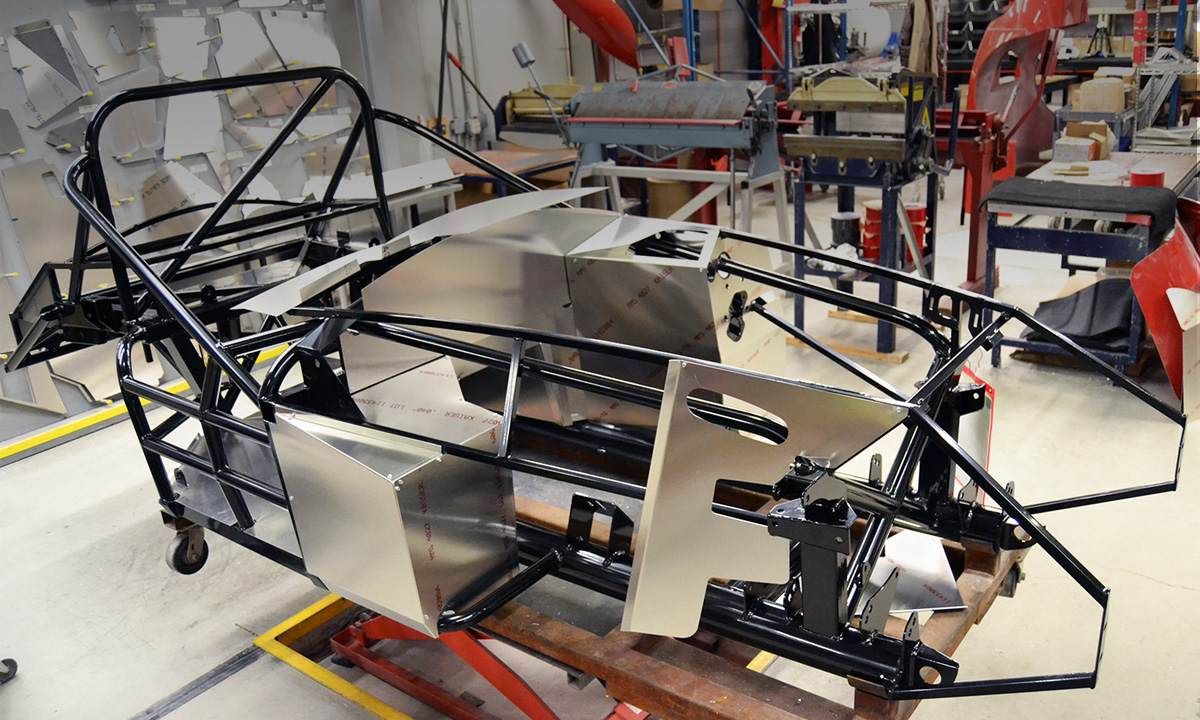

The modified roadster frame enjoys a serious cage thanks to the NASA and SCCA guidelines for open GT-1 cars. The differences in the frame and the tremendous amount of additional tubing mean that street car features like doors that are hinged have been replaced by NASCAR style side impact tubes. Frame mods accommodate mounting and shielding of the racing fuel cell, intrusion plates and racing seats.The chassis is about 15% more rigid than the Mk4 roadster. Most of the additional steel is for safety, rather than chassis rigidity. There is no backbone section to the frame, but the full race cage contributes more than that in added rigidity. Additionally, the fact that the cage is welded along with the frame means that the body needs to be cut along a line from the rear cockpit opening to the back of the roll bar legs.

We send along a carbon fiber cosmetic cover for this area. The FFR 3-link suspension is the most optimized race suspension we sell, and Challenge frames come ready to use that suspension. Owing to the increased amount of steel in the Challenge car chassis, completed vehicles typically weigh around 100 lbs more than standard roadsters.

When you see Factory Five cars winning national races or lifting the tires clear off the ground, check out the “straight-as-an-arrow” frame quietly doing its job. There is no finer replica frame. Period.

Our welded parts are made in the USA with American labor.

Our welded parts are made in the USA with American labor.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

Challenge Car Aluminum Panels

Underneath our hand-laid fiberglass composite body are almost 40 individual aluminum panels attached to the Factory Five Mk4 spaceframe.

Challenge Car Aluminum Panels

Even vintage 1960s cars like the original ACs, Ferraris and GT-40s used proven racecar construction methods of tubular frames and riveted/bonded aluminum panels.

The Challenge car chassis is built on the strong foundation of our world class Mk4 frame. Connected to that beautiful tube steel frame is an array of aluminum panels bonded and riveted in place like any good race car should be. Aluminum panels make-up the car’s sub-frame and liners.

The aluminum chassis panels found in our Mk4 combines this traditional quality with the latest CAD/CAM technologies and superior construction methods. The entire cockpit, trunk and engine bay of the Factory Five Mk4 is precision laser-cut 6061-T6 aluminum, without any fiberglass structural items. Underneath these aluminum panels, a matrix of steel tubing provides support surfaces for a close, tight-fitting installation.

Why 6061-T6 aluminum? Conventional 4000-series aluminum is easier to bend and form, but not as strong in tension. We invested in learning how to correctly form the 6061-T6 to get the benefit of increased strength for the same weight.

The strong foundation of our world-class frame combined with our aluminum chassis panels bonded and riveted to it represents just one of the major design and functional differences between the Mk4 and almost every other replica sold today.

The strong foundation of our world-class frame combined with our aluminum chassis panels bonded and riveted to perimeter frame tubing represents just one of the major design and functional differences between the Mk4 and almost every other replica sold today.

Challenge Car Composite Body

The Challenge Car Composite Body

Period-Correct Shape, Made Correct. Period.

The body shape of the Factory Five Mk4 is extremely accurate benefitting from, and a direct descendant of, two original cars, CSX 3042 and the late Dick Smith’s famous #198, CSX 3035.

The composite body is a one-piece, hand-laid vinylester part that is engineered to complement the strong steel and aluminum chassis, which provides structural support. The hood, doors and trunk have molded liners and come complete with hinges and pre-drilled mounting holes. The body shell is laminated to a thickness of 3/16” all around, with a .015” red gel coat outer finish.

The composite body is shipped pre-assembled to the frame. The parts are unfinished (requiring bodywork). Panels are CNC router trimmed.

We know molding. Since 1995, we’ve built and shipped more than 11,000 body shells and over 40,000 body panels, and built more than 100 complex molds and tools.

![]() “Station to station at Factory Five, it is clear that quality principles are in full force.”

“Station to station at Factory Five, it is clear that quality principles are in full force.”

Craig Fitzgerald | Editor, Hemmings Muscle Machines

Challenge Car Suspension & Brakes

Challenge Car Suspension & Brakes

The strong Challenge chassis is complemented by an outstanding and proven suspension and the ability to use a wide array of excellent brake packages. Suspension design and engineering is an extremely challenging endeavor. Over the years we’ve found what works best in the real world of racing. You can’t get lucky and you can’t say it works unless you prove it. The only way to prove it is at a track and under the most extreme circumstances over many, many years.

Our engineering team has paid it’s dues.

Front Suspension

Up front, the Factory Five Racing Challenge kit comes with a fully independent tubular front suspension with unequal length upper and lower a-arms and high-end Koni brand single-adjustable coil-over shocks (say that three times). Our car has earned huge praise and recognition for its suspension which delivers razor sharp handling and a comfortable ride.

Unlike the Mk4 kit whereby customers can use the front lower control arms from the Ford Mustang, the challenge kit includes the optional tubular lower control arm. The front suspension components are well engineered and bolt-on with ease.

For brakes the world is your oyster. Spec legal cars in the FFR-NASA Challenge series must wear Mustang Cobra brakes, but open classers and non-spec racers can run the optional Wilwood road race brakes.

With the Challenge kit, we supply the coil-over shocks, coil springs, custom mounts, spindle brackets, and upper & lower A-arms with ball joints and fasteners, all ready to bolt together.

Rear Suspension, FFR 3-Link for Pure Performance

The Challenge kit is set-up to utilize the 3-link suspension. The 3-link suspension is a great example of how racing and product development go hand-in-hand. After the inaugural season racing our Challenge Series cars in the Mid-Atlantic and West Coast series in 2000, we found the standard four link suspensions had a tendency to oversteer (similar to Mustangs) when pushed to ten-tenths competitive driving. Our engineers began working with customers, racers, and the team at the Bondurant School to develop a more neutral, racer-friendly suspension.

After more than six years of racing action and thousands of hours of brutal track testing, the FFR 3-link is recognized as a proven and worthy rear race suspension. It works wonderfully, aiding hook-up, eliminating bind and provides an amazingly predictable ride whether you’re at the track or on the street.

The 3-link suspension is designed to use the Ford 8.8” rear axle and includes a steel framework and panhard bar package that includes high-end Koni shocks.

Challenge Car Running Gear & Specifications

Challenge Car Running Gear & Specifications

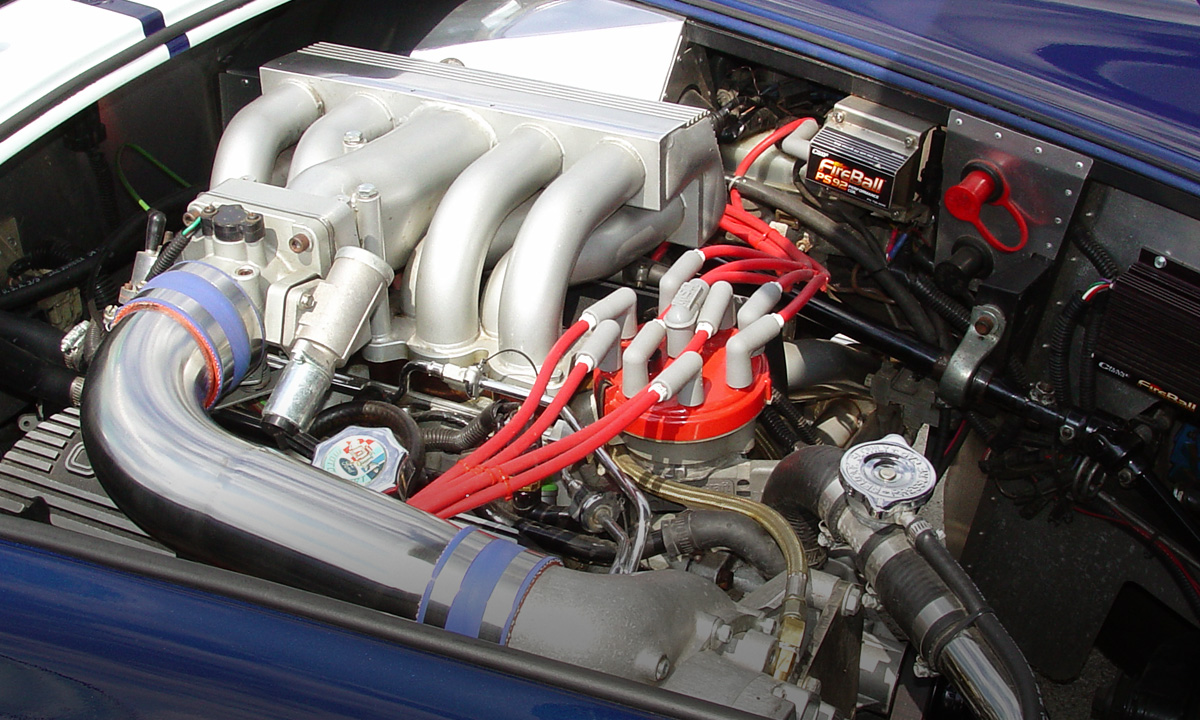

Whether you are racing in the FFR-NASA Challenge series or running an open class racer, you still have to select an engine and transmission to use with this car. We’ve built cars for our racing programs using the full range of Ford small-block and big-block engines. The aftermarket is alive with parts and services related to this category. Additionally, today’s modern running gear provides reliable performance for less money.

Engines:

In the early days most challenge car were built with spec Mustang running gear (engines/trans/rears). Nowadays with the proliferation of not only spec legal series cars, but monster open track customs, we can only tell you what fits (with respect to engines etc)… we can’t tell you what to use!

Transmissions

The challenge kit is ready to accept the full line of Ford and many aftermarket transmissions. While there is plenty of room in the transmission tunnel for older set-ups, we still prefer sticking with the newer running gear for affordability and durability. The stock Mustang transmission is either a T-5, T-45 or 3650. We have run T-5’s in our race cars for years with excellent results. Most racers choose the Tremec TKO transmission and upgraded heavy duty Ford Racing clutch.

Rear Ends and Gearing

The FFR 3-link suspension requires that you buy an 8.8” solid axle rear end. 1987-2004 Mustang GT’s were equipped with a few different gear ratios. The majority of the cars have a 2.73 ratio. There were optional performance rears that used a 3.08 ratio and many cars were built with automatic transmissions and a fun 3.27 ratio. Keeping in mind that the T-5 is an overdrive transmission, you have some space to improve the gear ratio with aftermarket parts without compromising the street manners of the car. The most common gear sets used on the track are 3.27’s.

Suspension

- Front suspension type – Independent double arm

- Rear suspension type – Solid Rear Axle 3 link with Panhard Bar

- Shock-Springs – Koni coil over with ride height adjustment

- Steering – Power assisted rack and pinion 2.6 turns lock-lock

- Brakes – Vented 13/11.65 fisc f/r disc brakes

- Wheels – 17" × 9" front and rear

- Tires – Toyo Tire RRs 255/40/17 front and rear

Vehicle

Weight – 2250 lbs.

Weight Distribution F/R – 46.2/53.8 (%)

Wheelbase – 90 in.

Overall length – 158 in.

Front Track – 58.5 in.

Rear Track – 58.5 in.

Overall height – 47.0 in.

Overall width – 70.5 in.

Ground clearance – 3.5 in.

Fuel Capacity – 22 Gallons

Construction

Layout – Front/mid engine RWD Roadster

Frame – Tubular space frame with integrated backbone

Roll cage – NASA Approved 1.5 in DOM tubing

Sub-structure – Aluminum panels riveted and bonded to frame

Restraint System – 5 point Simpson Harness

"...We like the Factory Five not only for the level of enjoyment a person can have with it strapped to his backside, but for the great engineering and business feat it is…"

Challenge Car Interior

Challenge Car Interior

The interior of the Challenge car is all about the business at hand. No carpeting or street seats here. You get all the functional interior pieces and trim that comes with the roadster, except for items that are not needed by racers. The Challenge kit includes a competition seat for driver, leather steering wheel, competition gauges, small competition windscreen, standard shifter and boot, dash, mirrors and Simpson harnesses are also included.

Sitting in the car you’ll find as large a cockpit that you have to step into (no hinges on doors). Following a careful entry and exit, you’ll find great race-car visibility all-around and an office that is well suited to the serious job at hand.

"...When it comes to bang-for-the-buck, Factory Five Racing's Mk4 is the Molotov cocktail of Replicas..."

Steve Temple, Editor Car Builder Magazine

Former Director of Marketing, Shelby American

Challenge Car Exterior

Challenge Car Exterior

While it’s true that most folks will only see you as you blur past them from 50 feet at more than 50 mph, a good number of people will look at your car up close in the pits. Just because this is a dedicated race car doesn’t mean the small trim doesn’t matter.

The Challenge car uses almost all the same high-quality trim items as the Mk4 roadster.

Windshield, Lighting, and Mirrors

The Challenge kit comes with a competition windscreen (the full framed chrome-on-brass windshield can be purchased as an option). The kit comes with original British style lighting and fasteners. These include the expensive Lucas twin filament red tail-lamps, amber turn signals, license plate light (some guys register their challenge cars!), and headlamps. The original chrome “Bullet style” racing mirror comes in the kit along with the classic pedestal mount rear view mirror.

Trim Accessories

Exterior trim includes the original chrome latches and handles (L-shaped for hood and T-handle for trunk all keyed alike), side louvers, front and rear quick-jack bumpers w/fasteners, and competition hood pins. A high quality hood hinge is an option.

The three-point roll bar of the roadster is replaced by the welded full cage of the challenge chassis.

Challenge Car Safety

Challenge Car Safety

In the world of hot rods, customs, and kits, we stand miles above the crowd. As the only replica company that has a dedicated racing series, we speak from a unique perspective.

Vintage components that are individually FMVSS compliant (ie. lighting, seating material, safety glass etc)

In the world of hot rods, customs and kits we stand miles above the crowd and it’s in great part due to our steadfast commitment to racing development and safety. It’s also because all of us share a deep love and concern for all the people who may ride in a Factory Five. That includes our families, friends and customers

The Challenge Series cars benefit from the following safety features:

- Complete NASA Approved competition roll cage with side impact bars, mounting for intrusion plates, footbox steel tubing protection and cockpit steel surround structure.

- Low vehicle weight, excellent weight distribution, and low vehicle center of gravity

- 3″ Simpson brand, full racing H-harness for driver and passenger.

- Collapsible steering colum

- Driveshaft safety bars/

- Front and rear energy absorbing crush zones.

- Energy absorbing tubular steel frame and aluminum chassis panels (not fiberglass).

- Manufacturing control that maintain high degree of consistency in welding and fabrication.