The Factory Five 818R race development program has been at full throttle this year. The goal is to make the 818 chassis the most track-capable street car in our line-up and to continue developing the platform for new products.

The 818 story continues to grow and the car is definitely earning its place in the Factory Five line-up. A little more than a year after production began, I am impressed with the number and scope of accomplishments that the newest Factory Five has racked up.

The 818 story continues to grow and the car is definitely earning its place in the Factory Five line-up. A little more than a year after production began, I am impressed with the number and scope of accomplishments that the newest Factory Five has racked up.

The team continues to work hard to make the platform stronger, faster, and offer more build options. Work has begun in earnest on a much anticipated removable hard top. Inspired by community-based CAD designs, we are making the coupe top removable, and importantly, retro-fittable to all 818S models.

Overseas, the 818 is bringing the Factory Five experience to more people in more countries. Right hand drive cars have been shipped to the UK, Australia, and the far east. As designed, the 818 is the most exported chassis kit we build. It is exciting to see Factory Five communities growing in different countries around the world.

Speaking of community, the 818 has a HUGE number of online builds where people are documenting their individual builds and experience. The customer stories are awe-inspiring. This year’s SEMA Show will highlight some of the variety of 818 builds and the flexibility of this exciting new platform. This is a huge e-mail, but it cannot include ALL of the great stories out there, so apologies to those amazing cars I’ve missed.

I am very proud of the entire team and the tremendous amount of work that has been done. The last update I sent out was in March, so this one is a bit longer than most. Hope you enjoy the update.

Dave Smith

President

818 Production Nears 300!

As of August 26th, 2014, chassis production reached 271 units! It has been a great year so far, and the team has ramped up production in a controlled and quality-oriented way. We are currently manufacturing one 818 chassis per day, and have decided to keep production at this level. The foundation of investing in technology that was laid before production began has paid huge dividends in quality and productivity with the 818. The new laser cutting machine has reduced inventory and increased through-put with high-quality, and our investing in molding technology has produced the best panels to date.

818 1st at NOPI Nationals 2014 & Profiled in UK Complete Kit Car

Tom won first place in the Street Kit Car division at this year’s NOPI Nationals with his 818S!

Factory Five customer Tom W. earned first place in the Street Kit Car division at the 2014 NOPI Nationals. His 818 was also featured in the most recent issue of Complete Kit Car in England. The 818 is a perfect match for the British market as it is right hand drive, uses running gear already in Britain, and is priced to keep VAT taxes low.

The article in CKC profiles Tom’s beautiful orange 818S and gives a quick overview on the design process of the car followed by the story of Tom’s build. Click here to read more.

Over 120 Customer Online Builds!

The 818 was developed, tested, and marketed along with the online Factory Five community, so it should be no surprise that there are a few customer builds documented on The Factory Five Forum.

The 818 was developed, tested, and marketed along with the online Factory Five community, so it should be no surprise that there are a few customer builds documented on The Factory Five Forum.

The real surprise is the amazing number and variety of builds, over 120 customer builds! These builds showcase some real innovation and remarkable craftsmanship.

Check out some of these builds like customer Gary N. from Hawaii whose stunning black 818S build photos always contain a hula girl doll! Click here to read the build stories on The Factory Five Forum.

Left: Factory Five customer Gary N. documents his 818S build onthe Factory Five Forum. Click here to read the thread.

Factory Five 818 Runs 56.28 Seconds at Lime Rock!

It has been a busy race development summer for the 818R. In this video, Factory Five Challenge Series National Champion John George runs 56.28 seconds. For anyone who has run at Lime Rock, this is an extremely fast time.

Climb onboard the 818R and run 56 seconds around Lime Rock Raceway.

Fast lap at VIR: 818R runs 2:04 in traffic!

Customer Brandon S. runs HARD at streets of Willow Springs

Grassroots Motorsports 818 Build Part 7 Released

The October issue of Grassroots Motorsports features part 7 of their excellent 818S build series articles. In this article, the car built at Very Cool Parts ends up on the ground and running. Click here to read more.

Factory Five 818 at the White House!

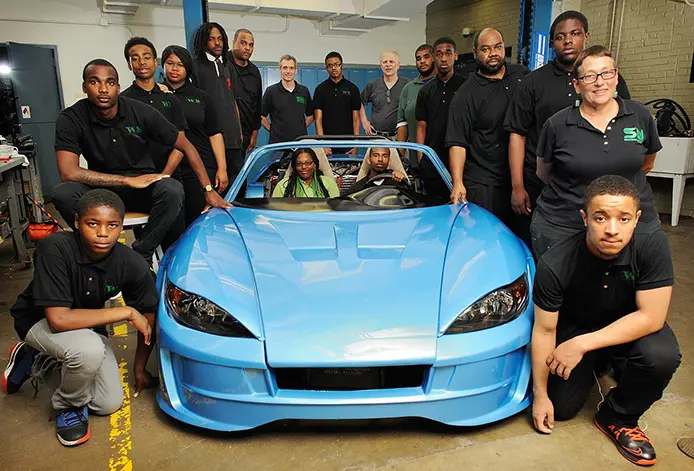

The accolades keep coming for the Factory Five 818! Simon Hauger and the kids from West Philly High School displayed their school-built Factory Five 818 at The White House in June as part of an event sponsored by President Obama’s administration entitled “Maker Faire”. The event highlighted DIY and modern technology that enables small companies, individuals, and enthusiasts to design and build innovative and exciting products.

Simon Hauger (standing center-left) and the entire West Philly High School tech team with the 100 MPG car they built. Read the full story here.

SEMA 2014 Preview

We’ve got big plans for SEMA 2014 and the 818! We will be bringing three cars, all very different. Our 818 street car will share space with the newest 818R (which is being race developed this Summer and Fall), and the exciting electric 818e built by Erik Hansen and EV West.

We’ve got big plans for SEMA 2014 and the 818! We will be bringing three cars, all very different. Our 818 street car will share space with the newest 818R (which is being race developed this Summer and Fall), and the exciting electric 818e built by Erik Hansen and EV West.

Todd B. and Keith P. from Six Star Cars are building an 818R for Spectre Performance. A number of customer cars are under consideration for Featured Vehicle locations.

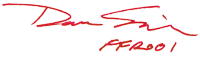

Our goal this year at SEMA is to show the variety of build types that this new car can be. Left: SEMA-bound 818R by Six Star Cars. Photo: The Factory Five Forum.

30 Day Build Video/Reality TV

The goal was simple and clear. Build a Factory Five 818R for under $30,000 in 30 days and run under 2 minutes at Grassroots Motorsports Ultimate Track Car Challenge held at Virginia International Raceway.

The goal was simple and clear. Build a Factory Five 818R for under $30,000 in 30 days and run under 2 minutes at Grassroots Motorsports Ultimate Track Car Challenge held at Virginia International Raceway.

What would normally be a huge challenge would be made even more difficult by the presence of a film crew and a production company hell bent on producing the first episode of a reality TV series.

We built the car in 30 days, and came in under budget, but the results at UTCC fell short with a blown head gasket and a heart broken team. We re-grouped and are heading back to the track in a month and plan on arriving at SEMA with a sub-2-minute 818R. More on this shortly.

Erik H. & EV West 818 Electric

’33 Machine’s 818E was tested by Autoblog.com.

’33 Machine’s 818E was tested by Autoblog.com.

In our last update, we told you about Factory Five Erik Hansen and his work building a battery-electric-powered 818S. Erik and EV West have since completed the car and successfully tested it on the street and at some local Southern California tracks.

Autoblog.com covered the car as a driving chassis (without body) and evaluated the handling characteristics and power of the 818E. Click here to read that story.

Autoblog Green covered a race day at Laguna Seca with alternate-powered vehicles and mentioned the now complete 818E. Click here to read that story.

Engineering Upgrades and New 818 Parts

In the last e-mail update, I asked a question about the interest in a removable hard top for the 818. The project was delayed by the launch of our 289 USRRC replica, and now our shaping bay is focusing on this high-interest hard top. While the hard top project is the largest of the 818 engineering challenges (and will likely take the most time), here is an update on the many other upgrades and changes we’ve been working on for the 818 platform.

Inspired by concept renders of an 818 coupe, the R&D team is working on a removable hard top that will work with the current 818S design. Above concept by Factory Five Forum member VMan using actual Factory Five 818S studio photo.

All-New Molds & Red Gel Coat Now Standard

Factory Five Ops Dir. Nate Johnson and Molding Chief Kyle Barros.

The original goal of the 818 was to provide thermo-formed plastic panels that would not require bodywork. That project was one of the few design goals that was not ready at product launch. The car launched with gel-coat white bodies and now we are changing to red.

Just last month, we’ve finished all-new molds and changed the gel-coat color to red. This has accomplished a better finish panel with fewer defects and has gotten us closer to our goal of a paint-free car.

818S Wiper Kit in Production

The 818S wiper kit is now in production. The wiper kit costs $225 and will be on our parts catalog shortly.

The 818S wiper kit is now in production. The wiper kit costs $225 and will be on our parts catalog shortly.

The kit uses the Subaru wiper motor/transmission and works with the stock wiper controls found of the factory Subaru turn signal stalk.

The kit includes wiper arms, blades, mounts and mounting hardware, as well as a two-piece drop-in fiberglass tray for the trailing edge of the hood. The factory hood will be trimmed on those cars using wipers.

New Carbon Fiber Parts & Process

Up to now, optional 818 carbon fiber pieces have been made by hand by our molding department in-house. We have had complaints about the finish (it’s not perfect), so we have invested in new tooling and a new outside carbon fiber molding supplier.

The new tools enable pre-preg carbon cloth to be used and autoclaved to result in an absolutely PERFECT carbon fiber part.

Click here to check out the parts catalog page.

New Aero Front Canards

Part of the 818R development program involved increasing downforce in the front and rear of the car. Up front, we designed a larger carbon front splitter and these cool new carbon canards.

These carbon fiber canards cost $199 for the pair and were designed for the 818R, but can be used on the street as well. Recommended to be used with rear wing for balanced downforce.

Click here to check out the parts catalog page.

All-New Padded Interior

The standard 818 interior panels are nice, but these new optional padded interior door panels and dash do not require any upholstery work, are easy to install, look great, and cost $550 as an option.

The standard 818 interior panels are nice, but these new optional padded interior door panels and dash do not require any upholstery work, are easy to install, look great, and cost $550 as an option.

This interior set comes in black and adds a rich finish to an 818S build. Left: New padded dash comes with door panels and is available in black.

Click here to check out the parts catalog page.

New Harness Bar Mount

Sales of the track-focused 818R have been good. However, many 818S customers are realizing that these cars are exceptional open track and autocross cars.

We’ve added a harness bar option to the 818S kit for customers who are taking their 818S models to the track. The harness bar costs $85 and comes powdercoated in black. It is designed to mount to the upper harness section.

Click here to check out the parts catalog page.

Soon to Be Released

At the request of customers and as a result of our race development and continuing work on the street car platform, we are almost finished working on several optional part packages. A new 6-speed transmission adapter kit is being developed. It will come with 2-wheel drive conversion coupling for use with STi 6-speed transmissions, 2004-2014. This was tested in our 818R. Not everyone is wild about the factory shifter, and we have tested and are almost ready to sell a super cool Billet aluminum shifter that provides improved precision and a shorter throw. Last, but not least, our shaping bay is busy with our new removable hard top design. These parts will all be available by SEMA 2014, except for the hard top (estimate six months).

The 818 is at the very head waters of an exciting new design, but even now, the cars are running extremely fast lap times and delivering REAL street driving manners. The success of the 818 is a pure function of our dedication to continuing to test and develop the car as well as the efforts of so many amazing and creative customers who have taken this design to new levels.