“Building a car from the chassis-up is the ultimate form of automotive self-expression. At the end of the day, it’s your car. Factory Five Mk4 Roadsters, like humans, share most of their DNA with each other, but in that fraction of a percent difference we see their owners’ individuality.

Photo by Chris Clerc

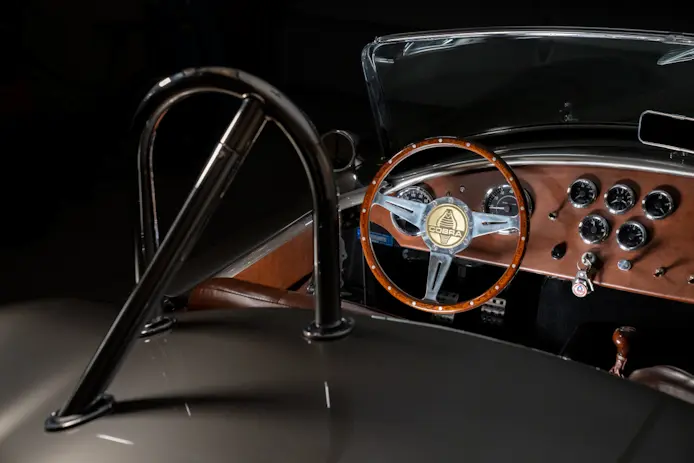

Mine can be seen in three specific principles that guided the build: sensorial experience, maximal reliability, and vintage feel:

Sensorial Experience

By this I mean that I wanted to use rich materials such as wood, brass, and leather to achieve a very specific aesthetic that would stimulate the senses to evoke in myself nostalgia for a more charming period in automotive history, and to (eventually) evoke in my son nostalgia for us, for his childhood. To accomplish this I modified the steering hub adapter to fit a walnut Moto Lita steering wheel, and I found a matching new-old-stock walnut Cobra shift knob made long ago by a small woodshop in New England. The interior is upholstered in aged Relicate Burlwood leather. Inspired by the 50th Anniversary Shelby Cobras, I had custom emblems cut from solid brass and engraved with my modified Cobra designs. Even the wheels exemplify the theme, with vintage-looking American Racing Shelby knock-off spinners that I custom cut to fit modern anthracite Mustang Bullitt wheels – a perfect juxtaposition of old and new. Lastly, the body color is a rare shade of silver used in a limited run of Bentleys with an extremely fine metallic flake that gives a more classic look.

Maximal Reliability

I plan to use this car to take my son on a tour of America’s top driving roads, so the drivetrain needs to be bulletproof. I chose a 6.2L LS3 crate engine, one of GM’s Connect & Cruise packages. This drivetrain gives me factory-caliber EFI, is associated with an abundance of parts, produces low engine stress by using the 430hp version with the mildest cam, and comes with a 50,000 mile warranty, to boot. There is never a question of if the engine will fire up when I turn the key; there is never consideration for temperature, or altitude, or any other external factor. I simply turn the key and drive. Every time.

Vintage Feel

While this drivetrain may remove some element of the vintage feel, I preserved it in other ways. The manual steering rack provides a level of communication with the road that simply cannot be achieved with hydraulic or electric power, and with the 20:1 Flaming River rack ratio parking is still done with ease. Similarly, the 3-link solid rear axle provides a uniquely vintage experience.

The process of building this car to bring these principles to life was incredible. I was well-prepared by my instructors Todd and Jim from The Mott Community College Factory Five Build School, and helped along the way by a series of professionals, now also friends, who made sure I never got to the wrench-throwing stage of frustration. Thank you to their independent businesses: RJ Designs, Mike’s Custom Wiring, Gaspars Customs, and Dylon the LS swap expert.

My 7-year-old son Remy and I built the car from April to December 2023. He was my right-hand-wrench countless times, and we found many tasks that suited him: he helped assemble the shocks, rolled the leather onto the dash, fit his little hand in the bellhousing to start the clutch line connectors, learned to use the electric rivet gun for panel work, and much more. This car is truly ours, not mine.

The build process was every bit as much fun as driving the car has been, and I really enjoy driving this car – I put nearly 1,000 miles on it in the first 4 weeks after it was finished. I pick Remy up from school in it, take him to piano class and soccer in it, and sometimes I just take it out for the pure, unadulterated, stress-relieving experience of driving alone on a twisty Arizona canyon road in a car that has my style in its DNA. Thank you, Factory Five, for memories made and still to come.” -Vijay K.

Photos by Gustavo Moser